- Casting

- >

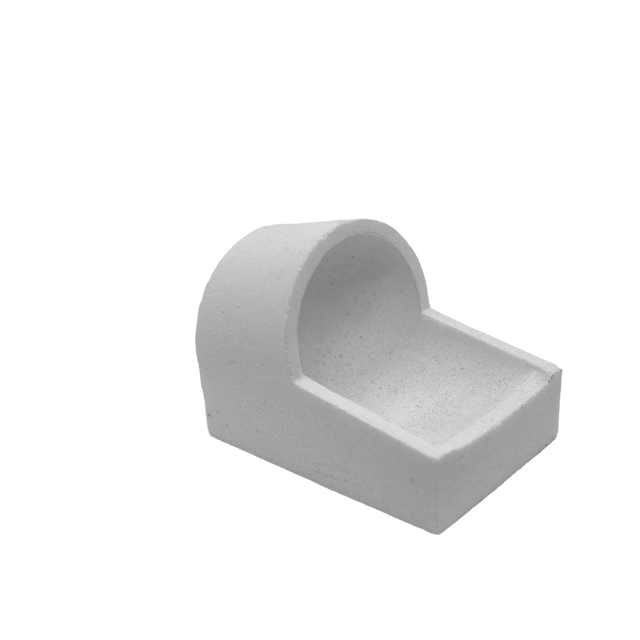

- Casting Crucible

Casting Crucible

SKU:

Non-contaminating & fits to any standard type or broken arm centrifugal casting machines

CLAY SLOTTED

CLAY-S

718-001

1,000°C / 1832°F

63.20 x 48 x 42.50

-----------

QUARTZ HOODED

QHN

719-000

1450°C / 2642°F

63.29 x 48.60 x 43.70

-----------

QUARTZ SLOTTED

QSN

720-000

1450°C / 2642°F

66.35 x 49.15 x 41.70

----------

QUARTZ MINI

QMN

721-000

1450°C / 2642°F

48.65 x 34.10 x 37.14